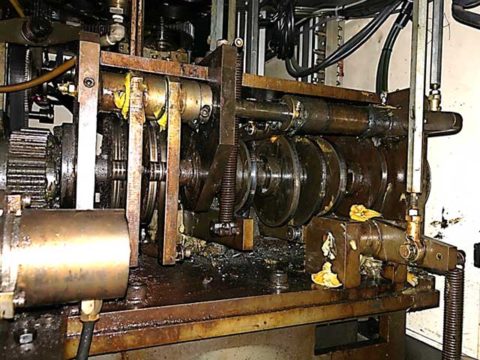

- Dismantle and inspect the equipment to confirm whether normal operation can be continued using the actual equipment.

This is a preventive maintenance procedure in which necessary repairs or replacement of parts are performed to restore the initial performance. - Overhaul work includes disassembly, cleaning, repair/replacement, lubrication, assembly, and adjustment.

An overhaul is necessary to maintain efficient and economical operation at all times. - In the case of mechanical parts, lubricate the parts where friction occurs between parts.

As the oil degrades over time, the friction between the parts increases, causing wear, which in turn causes metal fatigue, which in turn causes equipment failure. - In addition, the aging process causes rusting of parts, foreign matter adhesion, and contamination, making it impossible for the equipment to operate with precision and in good condition.

- We will also suggest the replacement of any purchase arrangement parts found during the estimate.

For parts that are no longer available due to age or discontinued production, alternative parts will be designed and considered. - Additional costs may be incurred after the start of overhaul work due to replacement parts that cannot be found without disassembly.